As major projects such as HS2 look set to revolutionise the way in which data is collected and handled in the geotechnical sector, Philip Ball, group technical director for SOCOTEC, looks at the growth in digital development and the impact this will have on the efficiency of project delivery.

As major projects such as HS2 look set to revolutionise the way in which data is collected and handled in the geotechnical sector, Philip Ball, group technical director for SOCOTEC, looks at the growth in digital development and the impact this will have on the efficiency of project delivery.

As an industry the geotechnical sector has always been quite manual when it comes to site reporting, with many engineers relying on basic tools to record information. However, in a recent survey by GE Magazine more than 80% of respondents reported an increase in use of digital data over the last five years. Nonetheless, more than half of respondents said that the transfer of data, and knowledge sharing were still among the biggest challenges presented by this growth in digital data use.

Improving efficiency

As the industry starts to recognise the need to change the ways in which they deliver their projects in order to achieve better results, improve efficiency and productivity, we have looked at our own systems to ensure that we are working as efficiently as possible, providing our clients with integrated collection and validation of data for all types of geotechnical work.

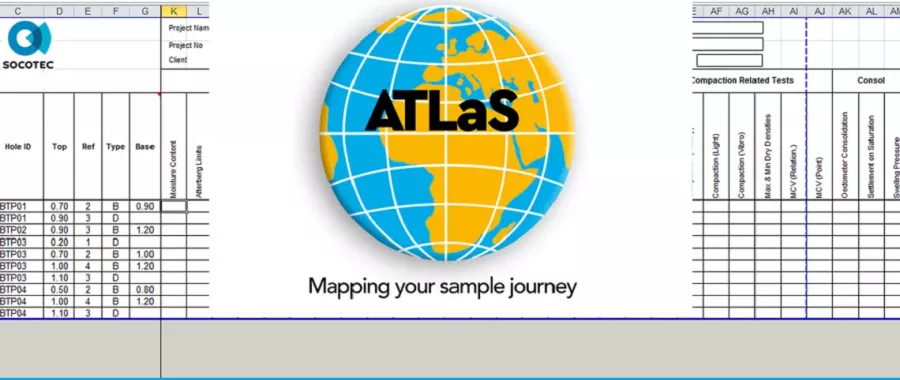

Our SILAS (Site Information Logging and Storage) app allows us to offer clients an integrated collection, validation and handling system for most types of geotechnical field work, allowing drillers and engineers to send data gathered on site to laboratory server as soon as it is available. This not only saves vital time in the investigation process, but also helps reduce paper use, boost efficiency and support sustainability initiatives.

Specially developed for the geotechnical industry, SILAS allows engineers to input and store a large amount of complex data regarding strata descriptions and site records, eliminating the risk of transcription errors to maximise data recording precision. The app is protected by multi-layered security and is integrated with a web based portal system, MiPortal, for online viewing of the site operations, validation and scheduling of off-site testing.

The increased use of technology to record information allows our skilled engineers more time on investigations and less time on data entry and administration. Our ambition has always been to enable drillers and field technicians to enter data once only and make it available to our engineers and the client's team immediately. Access to early information allows both parties to monitor progress and for the designer to make changes if required along the way. They can also begin to schedule laboratory testing immediately.

Equally, we have ensured that the three phases of work that make up a borehole record - driller's logs, engineering descriptions and laboratory tests - are produced seamlessly with absolutely minimal re-entry of data.

AGS data

It is interesting to observe how the use of AGS data is being misaligned with the ambitions of BIM. The Government’s drive to have BIM deployed on all its projects is a welcome advance but the geotechnical work that precedes that modelling is not yet compatible. Although AGS goes a long way to share the digital records of the ground it doesn’t fit in BIM models, only GIS systems that precede the full BIM representation. It should be noted that BIM is an entire process of data definition, control and sharing and the visualisation in the popular 3D models is only one aspect of it.

There is a gulf between the application of specific unitary information – a water treatment system for instance – and the factual records about the construction below ground and the main structure. As an example, in situ parameters for the soil or concrete strengths are not represented in BIM models because we can’t yet define how to represent a result form a sample to a specific location. One set of cubes may represent 10m3 of concrete poured in several locations. How can we represent that to add value to the model? There has been good work done on this type of issue but it is far from complete.

Want to find out more about SOCOTEC's ground investigation services?

You might also like

Add new comment