During demolition and construction projects, especially in densely populated urban environments, dust, vibration and noise can pose issues for neighbouring businesses, local residents and the surrounding community. The creation of some levels of these pollutants is unavoidable, but construction firms are increasingly required to demonstrate that they are taking proactive steps to minimise the impact that their activities have on the environment and prove that they are operating within acceptable limits.

Environmental monitoring is therefore increasingly mandated on all types of development projects.

In this blog, Mark Asemota, SOCOTEC Monitoring’s environmental monitoring manager, outlines why environmental monitoring is important and how the resulting data can help site operators and project managers to keep their projects on time and within budget.

Why is environmental monitoring important?

When undertaking any kind of development works – whether that’s the construction of roads, bridges, buildings or other infrastructure – there is an impact on the surrounding environment. The most common environmental impacts, to varying degrees, include:

- Increased particulate matter concentrations potentially affecting air quality, which could pose significant health risk to people within the surrounding areas

- Exposure to vibration, which can lead to long-term irreversible health impacts for people in the vicinity and structural cosmetic damage to buildings

- Heightened noise levels, which could damage a person's hearing

Given the potential severe impacts of the above if left unmanaged, environmental monitoring has become an essential component of any demolition and construction project for a number of key reasons.

Provides baseline data to define starting points

Before any demolition or construction works commence, environmental noise, vibration and air quality surveys should be carried out to establish the ambient levels of the measured variables, as well as allowing for a baseline monitoring period to gather more information on a particular site. This will help construction managers to identify what the starting levels of dust, vibration and noise are and set acceptable parameters for them once works get underway.

Ensures compliance with planning conditions and site requirements

Each construction site is subject to different requirements, so every environmental monitoring system should be treated on a case-by-case basis. If the pollutants generated from a construction site will likely cause issues for local residents, local councils will not approve planning, so thresholds should be set in accordance with individual site operating conditions and national standards, with monitoring in place to ensure these limits aren’t exceeded.

Local councils are increasingly acting upon nonconformities, so alarms and mitigation measures should be set at pre-defined points so that suitable controls are in place to limit the levels of dust, noise and vibration being generated for the duration of the project. If sites are approaching their limits, additional reduction measures should be implemented or works temporarily halted to avoid penalties.

Provides evidence in the event of complaints or legal challenges

Often, complaints faced by construction sites from local councils or residents relate to the dust, vibration and noise being generated. Collecting regular monitoring data ensures that site operators have the evidence to demonstrate to communities and regulators that building activities are falling within acceptable levels. This can help in the resolution of any complaints and protect construction companies from claims or unnecessary project delays caused by the unplanned cessation of works while investigations take place.

Early identification of issues

To ensure that construction activities do not give rise to any exceedances of acceptable levels, numerous pre-defined alarm levels can be set to provide early alerts should levels of dust, vibration or noise begin to rise. If construction activities are nearing nuisance levels, appropriate corrective action can be taken to keep levels within the safe limits.

If additional mitigation measures are required, ongoing environmental monitoring will provide evidence that the techniques used are effective and, if not controlling levels as predicted, highlight any areas which require additional attention.

Reduce business risk and improve project efficiency

As well as alerting site operators when works are approaching nuisance levels so that corrective action can be taken, environmental monitoring also serves to identify scenarios where levels are much lower than the acceptable limits. This allows project managers to adjust the programme of works to maximise operations while still abiding by the stated limits, perhaps increasing the rate of demolition and saving time and budget.

Types of environmental monitoring provided by SOCOTEC

SOCOTEC provides a range of environmental monitoring solutions for all types of construction and demolition projects, including:

- Air quality assessment and monitoring to measure Particulate Matter (PM10, PM2.5, PM1) and Total Suspended Particulates (TSP)

- Industrial effluent monitoring, analysis and consultancy

- Contaminated land investigation and consultancy, including groundwater sampling, radiation monitoring and hazardous materials surveys

- Earthworks and remediation support including waste management advice, waste classification and WAC testing and materials management plans

- Advice on and monitoring of risks from buried asbestos during construction work on brownfield sites, including airborne fibre monitoring

- Gas monitoring to measure NO2, NO, CO2, O3 and dust/landfill monitoring (with instrumentation for hire, sale and service)

- Environmental noise assessment and monitoring, including scenario modelling using specialist software

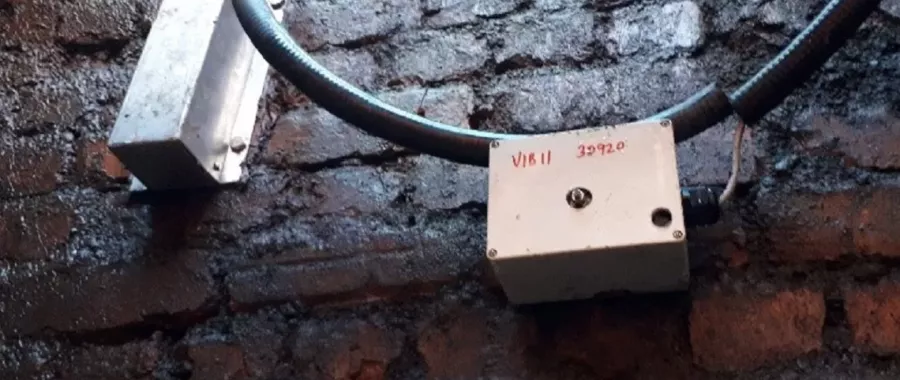

- Vibration monitors (FBA, MEMS and Geophones with selectable standards) to measure Peak Particle Velocity (PPV) and Vibration Dose Value (VDV)

- Stack emissions monitoring accredited to ISO 17025 and MCERTS

- Weather station monitoring to measure wind direction, wind speed, relative humidity and temperature

- Personal exposure monitoring to hazardous substances, noise, vibration and radiation, and provision of occupational hygiene consultancy.

If you have an environmental monitoring requirement that you wish to discuss, please get in touch.

Want to find out more about SOCOTEC's environmental monitoring services?

You might also like

Add new comment