Mick Pratt, commercial director, Built Environment Services, SOCOTEC, looks at the unique properties of ozone that make it an ideal water treatment solution for heads of production in UK industry.

According to Defra, the demand for water from England’s industrial and commercial sectors has been declining for more than 60 years. However, over the same period, a growing population has resulted in significantly increased water usage from households, and since 2003 rates have soared by around 80 per cent in Britain.

With this in mind, an increasing number of businesses are recognising the financial incentives for being more resource efficient and are reclaiming the water they use throughout their operations. For those recirculating water across their premises – such as in production facilities with washing lines, or data centres incorporating rapid liquid cooling technology – effective disinfection should be a priority for those responsible for production and other key duty holders.

Water can become contaminated through a number of different means, particularly if left without adequate treatment. This can result in costly disruptions to operations as well as health and safety issues. Traditionally, organisations that use process water systems rely on biocidal products to treat their supplies which are, historically, halogen-based chemicals such as chlorine, bromine or chlorine dioxide.

While these disinfection agents are effective methods of eliminating pollutants, halogen-based solutions do have their drawbacks. These include issues around their environmental impact as well as their perceived impact of chemicals on water quality. For instance, in some cases, chlorination can cause the formation of hazardous by-products after treatment, such as the carcinogenic trihalomethanes.

Powerful yet traceless

In an increasingly environmentally conscious world, these downsides have resulted in the rise of more innovative methods of water sanitation that don’t depend on halogen-based biocides. One such technique, being used throughout a number of different sectors, is ozone technology.

Ozone is a form of oxygen that has one extra atom, meaning it is highly reactive. Once the compound is dissolved in water, it becomes an extremely powerful and environmentally friendly biocide which is approximately 50 times more reactive than chlorine, the conventional alternative.

When actuated, ozone technology eliminates bacteria, viruses and microbial cysts and other unwanted contaminants in water supplies in an extremely efficient manner. Unlike other disinfectants, it does not combine with organic materials to create toxic by-products or residues during the sanitation process. In addition, the substance completely breaks down naturally, leaving no trace of itself after disinfection.

In terms of resource efficiency, this provides a significant advantage over halogen-based forms of disinfection. Instead of being flushed away, ozone treated water can be reclaimed and reused a countless number of times without losing any quality. This can prove to be beneficial for process waters and other environments where once through or the continual recirculation of water is needed for operations.

A trusted treatment method

Today, ozone is also used by beverage producers around the world to disinfect bottled drinking water. Due to its auto-decomposition properties, bottling plants using ozone can ensure that products have a maximum shelf life and are completely free of disinfection agents. In addition, by making use of ozone technology within clean in place (CIP) systems, end-users can significantly cut down on operational down time, resulting in an extremely cost-effective process.

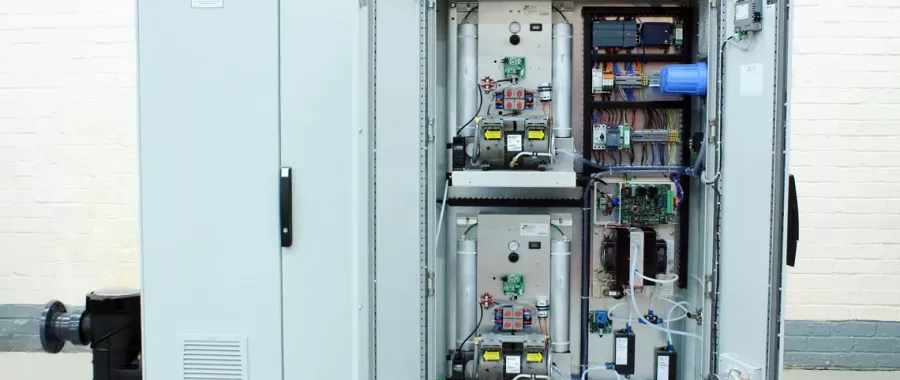

The most advanced ozone equipment is developed with efficiency in mind. OCS disinfection units, for example, ensure minimal oxygen demand and energy consumption during operation which can result in further financial savings for users. Coca-Cola HBC Ireland and Northern Ireland, which uses ozone on its bottling lines, is able to save millions of litres of cooling water for every year of operation. You can find out more about their success with ozone water treatment technology, here.

By upgrading to ozone equipment from traditional methods of water treatment, process leaders can ensure they maintain the highest levels of hygiene as well minimise the risk of disruption to their operations.

Want more information and advice on water treatment?

What water system management challenges do you face, and could ozone technology help? Leave a question below for our team of water treatment experts.

Want to find out more about SOCOTEC's ozone water treatment services?

You might also like

Add new comment