While the use and production of new asbestos-containing materials (ACMs) has been banned in the UK since 1999, a large proportion of railway infrastructure still contains the fibrous mineral – often unbeknownst to those managing them.

Under Regulation 4 of the Control of Asbestos Regulations 2012, the duty holder is responsible for managing the risk of ACMs in non-domestic premises by identifying, locating, monitoring and, where necessary, ensuring the safe removal of asbestos. The Office of Rail and Road (ORR) clarified that ‘non-domestic premises’ included railway lineside structures, railway vehicles, rolling stock, train stations and other public buildings, so the rail sector is legally required to ensure there are systems in place to manage the risks that asbestos poses and protect the health of workers and the general public.

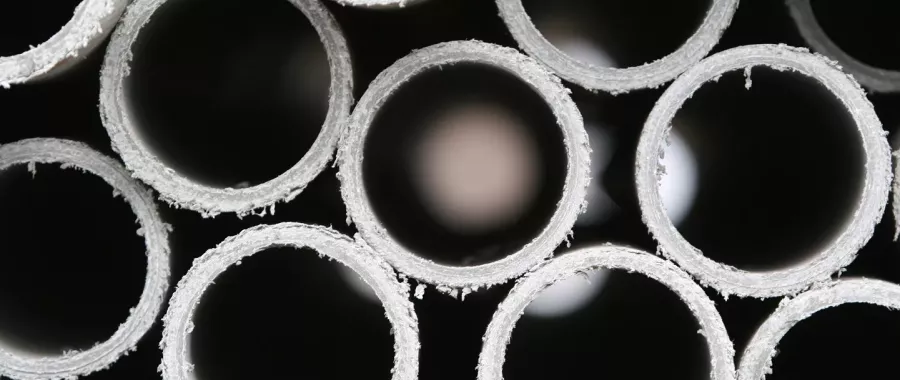

Used in the construction and maintenance of trains, locomotive components and railway infrastructure, the fire retardant and insulating properties of asbestos made it an ideal material for lining carriage walls, lagging pipe work, brake pads, packing piston cylinders, boilers and heating systems. Prior to any planned building work on trains/buildings, duty holders are required to undertake a management, refurbishment or demolition survey, dependent on the nature of the construction taking place. These often require samples of ACMs to determine the extent of the risk of asbestos exposure in terms of fibres potentially being disturbed and becoming airborne. Specific procedures have therefore been put in place to ensure that each sample is analysed as accurately and precisely as possible.

Surveying and risk assessments

Once a request for asbestos sampling has been acknowledged, the scope of work is fully documented and agreed with the client. The order will be officially received and processed, before a surveyor is scheduled for a site visit to inspect and record the location, quantity and type of the suspected ACMs. As part of the procedure, a clear statement and record of the survey is noted beforehand to inform the relevant bodies of the scheduled work.

According to HSG248, the collection of representative samples of the suspect ACM, will, following thorough analysis, determine whether the fibrous mineral is present, and, if so, confirm the type(s). However, the sampling process carries the risk of potential exposure to disturbed asbestos fibres, so prior to samples being taken, a risk assessment is required on site to set out the appropriate control measures and PPE to be carried out by a competent individual.

During the risk assessment, all areas within the premises are visually examined to check for and inspect potential/additional ACMs. This allows the surveyor to identify locations for sampling to take place, as well as assess materials for any difference in size/appearance. It is of paramount importance that the location of asbestos within the premises is known, as otherwise all areas should be presumed to contain ACMs until strong evidence proves otherwise.

Bulk sampling procedures

Much like the surveying process, the sampling strategy that is carried out depends on the type of ACM suspected to be present. To determine the specific sampling strategy required, surveyors must take into consideration such factors as the size of the site and its individual rooms, level of occupancy and the activity undertaken in the area. Visual examinations of each material will check the type, colour, depth, texture and coating in order to determine which areas can be used for sampling purposes.

Bulk sampling procedures will vary dependent upon the material being inspected, with HSG264 in place to recommend the appropriate sampling method for spray coatings, thermal/pipe insulation, insulating board, asbestos cement, floor and wall coverings, gaskets, rope, paper, textiles, felt, textured coatings, debris and dust. Surveyors take a bulk sample of the material(s), ensuring that it is truly representative of the product it is taken from. Each sample must be of an adequate size and surface area in order for the lab to analyse it correctly, which tends to be around 3-5 centimetres squared on average. There must also be a sufficient number of samples taken to gain an accurate representation and analysis of the whole material, and this again depends on quantity, range and variation.

Once the samples have been taken, they are individually sealed in a labelled container, with the correct information logged for each sample. This includes a unique sample number, the date that the sample was taken, the name of the person who took the sample, the name of the client and the location that the sample was taken from on site. A marked up drawing of the site with sample locations should be made. The sample is then sealed again in a second separate container or polythene bag to prevent the release of airborne fibres. Finally, smartphones featuring Asbestos Management Software (AMS) are updated to further ensure the consistency, accuracy and high quality of the results gained during the sampling process.

Transportation and preparation

To avoid cross contamination while in transit, each double bagged sample is transported back to the laboratory in a rigid box, where SOCOTEC’s lab technicians log each individual sample using the information provided on the labels.

There are various methods to prepare the sample for inspection, each of which is dependent upon the material being analysed. Preparation is conducted within a secure dust cabinet to prevent the risk of cross contamination and the release of airborne fibres into the laboratory. Acid digestion is a popular approach, as it is an effective means of separating the fibres from textured coatings, cement and powdery insulation materials, dissolving away the majority of the material and leaving behind a small quantity of fibres to test (asbestos fibres being resistant to acid digestion). Drying is another recommended option for preparation, although particular care needs to be taken when handling the samples, as dust is easily generated and released.

Sample inspection

Following preparation, the fibres are inspected under low power magnification using a stereo microscope, all the while making sure that the sample remains in the dust cabinet at all times. Suspect fibres are then extracted for analysis before being mounted between a glass microscope slide and cover slip using an appropriate Cargille refractive index liquid.

The optical properties of each fibre are analysed using polarised light microscopy at a high magnification of x100 or greater, allowing lab technicians to identify the specific asbestos type present in the sample and complete the corresponding data sheets. All test reports must meet ISO 17025 requirements, which means that they must clearly state whether or not asbestos was found, as well as indicating the type(s) of asbestos identified.

AMS is updated once the asbestos sample has been identified – this supplies vital information on the results of the sample testing to the client, including a survey summary and the follow-up actions required. A summary report is then drafted to conclude all of the findings from the survey, sampling and inspection procedures.

Storage and disposal

If further analysis is required, the sample is safely stored for future use. Samples are kept for a minimum of six months before they are classified as asbestos waste and properly disposed of from the laboratory. Health and Safety Guidelines state that the asbestos waste is double wrapped and labelled accordingly, and is then either deposited in a sealed skip, using a registered waste carrier or on a licensed disposal site.

As a leading provider of asbestos management and consultancy services across a range of sectors and property types, SOCOTEC offers an extensive network of in-house UKAS accredited testing laboratories that carry out asbestos sampling and material identification.

Does your business require assistance with asbestos compliance?

SOCOTEC offers a comprehensive programme of asbestos consultancy and management services.

You might also like

Add new comment