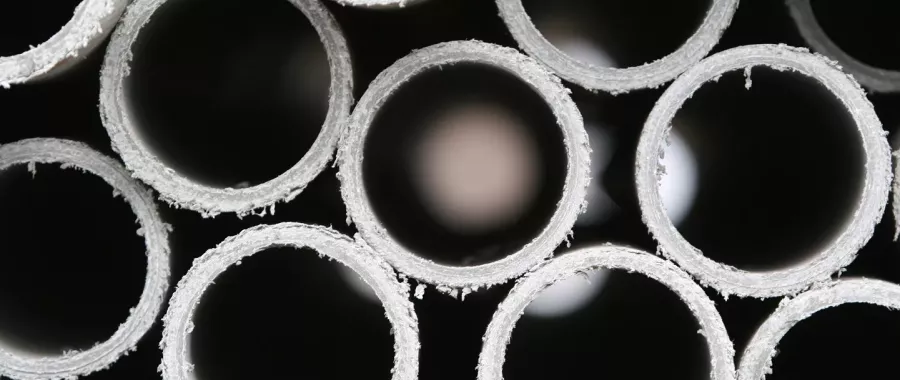

In the early 20th century, asbestos was used within pipes and insulation in both domestic and commercial properties to heat water and prevent condensation. Brown asbestos (amosite) was most commonly used within water insulation products due to its high resistance to heat. Furthermore, chrysotile (white) asbestos was used in pipes, gaskets, cement sheets and asbestos cement for its durability.

Present in both residential and commercial properties, asbestos in plumbing can vary significantly in terms of its overall appearance and texture, making it more challenging to identify. In particular, water pipes that are insulated with asbestos are usually covered in a protective coating, which is often painted and therefore even harder to distinguish. There have also been occasions where paint has been found to contain asbestos, too.

Common locations of asbestos in plumbing materials include:

- Insulation – asbestos was often applied to water pipes, on boilers, calorifiers, on tanks and to flue pipes. These can be located in plant rooms, loft spaces, ceiling voids, riser cupboards and floor ducts. The asbestos insulation is either hand applied directly to the pipework, boilers, water tanks or calorifiers, or in the form of pre-made sectional pipe insulation wrapped in a textile ‘plumbers wrap’. Asbestos insulation (lagging) was applied wet, so residue can be found on brackets and other surfaces near to pipe runs (even when the original pipe lagging may be removed)

- Pumps, valves and gaskets – asbestos compressed gaskets have been used extensively

- Heat shields – installed around hot water heaters (often made of asbestos millboard)

- Joint compounds – used around pipes due to its insulating properties

- Asbestos cement – used to make products such as flue pipes, toilet cisterns, water tanks and rainwater goods, as it was resistant to internal and external corrosion. Bath panels – older bath panels were often manufactured using asbestos cement or asbestos-insulating board.