The next generation of assessing integrity and longevity of your foundation structures has arrived with our Thermal Integrity Profiling service.

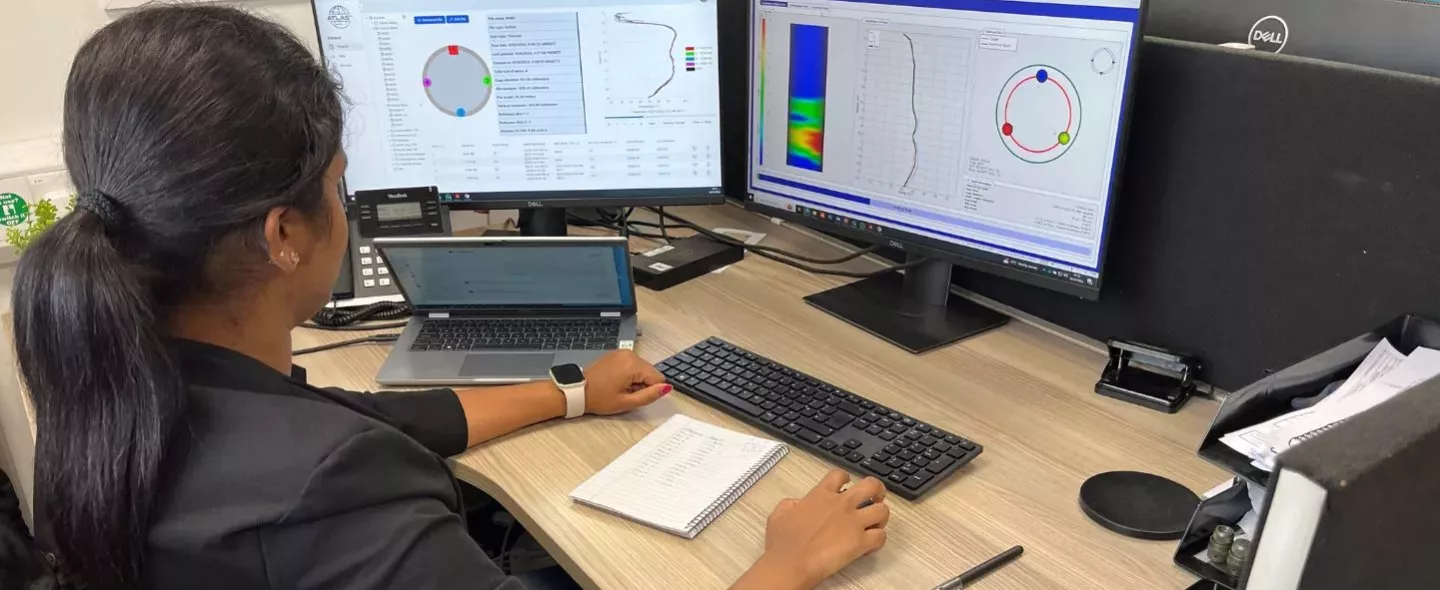

Our advanced testing provides critical insights into the homogeneity of piles and diaphragm walls for the whole cross section, in real time, if required, safeguarding against potential structural anomalies and dramatically reducing wait times, aiding productivity on live construction sites.

In the construction industry, ensuring the quality and consistency of foundational elements such as piles and walls is crucial. Thermal Integrity Profiling addresses these real-world challenges by detecting major voids, honeycombing, and inclusions that could compromise the safety and durability of structures. By identifying such issues early, contractors and clients can mitigate risks, reduce potential future costs, and ensure compliance with regulatory requirements.

Talk to our experts

Thermal Integrity Profiling

Our Approach

Our approach is rooted in a network of industry-leading experts, with experience and knowledgeable insights. Our team of experienced site operatives, located strategically across the UK, offers rapid response times and tailored solutions, ensuring our clients receive the full attention and expertise needed.

Our approach is rooted in a network of industry-leading experts, with experience and knowledgeable insights. Our team of experienced site operatives, located strategically across the UK, offers rapid response times and tailored solutions, ensuring our clients receive the full attention and expertise needed.

Learn more

What is Thermal Integrity Profiling (TIP)?

The Thermal Integrity Profiling (TIP) method measures the elevated heat during the hydration process of concrete to assess the integrity of cast-in-place foundations along their entire length and cross-section. Embedded thermal sensors placed directly into the concrete for bored/CFA piles and wall panels make the temperature measurements.

How does Thermal Integrity Profiling (TIP) work?

The temperature measurements are directly related to the cement content, concrete volume, and concrete quality. The temperature sensors are reading the localized temperature and are affected by any deviations in the surrounding area of the sensors, including the area outside the reinforcing cage. This ability to assess both inside and outside the reinforcing cage allows for 100% of the cross-section to be evaluated via the Thermal Integrity Profiling (TIP) method.

What are the key benefits of using Thermal Integrity Profiling (TIP)?

Results are typically viewed live via the cloud based software on a regular basis, allowing the data acquisition to proceed with no site presence required. The data loggers remain connected to the Thermal Wire cables from time of concrete placement until the concrete in the pile has reached its peak temperature. Thermal Integrity Profiling is completed during the early portion of the hydration process, up until the peak temperature, typically within 48 hours of casting, the analysis will be done very early in time, allowing for remedial actions or an accelerated construction schedule, unlike the traditional methods.

In addition to determining concrete integrity, Thermal Integrity Profiling (TIP) will also reveal reinforcing cage eccentricities by comparing measurements from radially opposite locations versus the average value at the same depth. If a single measurement location is warmer than the average temperature for a given depth and the radially opposite measurement is cooler than this same average, this would indicate that the temperature sensor with the warmer reading is closer to the pile core while the radially opposite temperature sensor is closer to the surrounding soil interface, indicating the cage is not concentric with the hole. The thermal data can reveal the cage eccentricity, the direction of cage shifting, and the loss of concrete cover outside of the reinforcing cage due to the reinforcing cage eccentricity.

The only method to assess piles or wall panels of non-uniform shape

Can Thermal Integrity Profiling (TIP) be performed on all types of cast in place foundations?

Thermal Integrity Profiling (TIP) is applicable and commonly used for all bored, auger cast in place and CFA piles from 300mm (single wire deployment) to 2,400mm diameter (8 wire deployment). Rectangular wall panels of any configuration installing one wire per 1m horizontal spacing.

What other clear advantages of Thermal Integrity Profiling (TIP)?

Piling crew safety is enhanced, particularly with sectional cages and reduced handling of joints. Reduced contact with hazardous materials in post grouting of access tubes. Additionally, there is generally a savings in labour and material cost.

Let's Talk

We're here to support all of your Thermal Integrity Profiling needs

Check out our other Pile Testing Services

Check out our latest news & media